- HOME

- About

- Product

- Business

- Case

- Solution

- News

- Contact

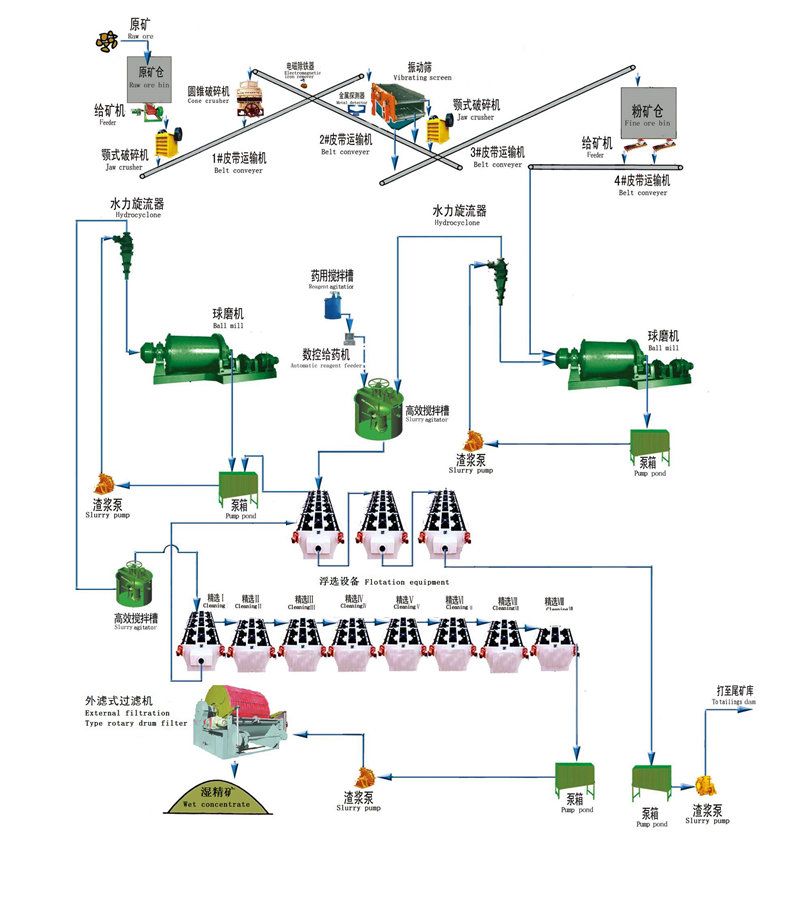

The gold ore flotation process is suitable for the treatment of gold-containing sulphide ores with finer, more buoyant gold particles. During the flotation process, the sulphide ore is enriched in the sulphide concentrate as a gold carrier. Flotation can also be used to treat polymetallic gold-bearing sulfide ores and carbonaceous ores. In addition, the "hard-to-tolerate ore" that cannot be directly treated with the amalgamation method or the cyanidation method also needs to be treated by a joint process including flotation.

Flotation equipment mainly refers to various types of flotation machines, flotation equipment such as new flotation columns, and is also used in individual gold mines.

XJK flotation machine is a traditional self-priming flotation machine, SF, BF flotation machine is a new type of self-priming flotation machine.

Inflatable mechanical stirring flotation machine is currently the most competitive flotation device. This type of device has the advantages of simple structure, air filling and uniform dispersion, low impeller rotation speed, low energy consumption, and light wear.

No.158 Linglong Rd, Zhaoyuan City, Shandon Province, China

COPYRIGHT (©) 2017 烟台市富林矿山机械有限公司 网站备案:鲁ICP备13032165号 Power by: Hicheng